Discover how ERPNext can revolutionize your manufacturing business with tailored solutions and expert implementation by Midocean Technologies.

Everything you need for Manufacturing

Plan, produce, and deliver on time with a single, fully integrated ERPNext solution for manufacturing. From BOM to finished goods, control every step with real-time visibility.

- End-to-end manufacturing – from quotation to dispatch

- Real-time shop floor, WIP and inventory tracking

- Production planning, capacity planning & costing built-in

Struggling with spreadsheets and disconnected systems?

ERPNext helps manufacturing companies unify production, inventory, purchase, sales, and finance in one platform so your team works on a single source of truth.

30%

Faster Production Planning25%

Reduction in Stock-outs100%

Traceability Lot to InvoiceWhy ERPNext is Perfect for Manufacturing

An open, flexible, and scalable ERP designed with manufacturing at its core – helping you digitize every process from raw material planning to final dispatch.

End-to-End Visibility

Track every material, job card, and work order with complete visibility across production, inventory, quality, and finance in real time.

Built-in Manufacturing Intelligence

Get accurate production costs, material consumption, machine utilization, and delivery performance with powerful reports and dashboards.

Flexible & Customizable

Tailor workflows, approvals, print formats, and reports to your unique manufacturing processes without heavy licensing or vendor lock-in.

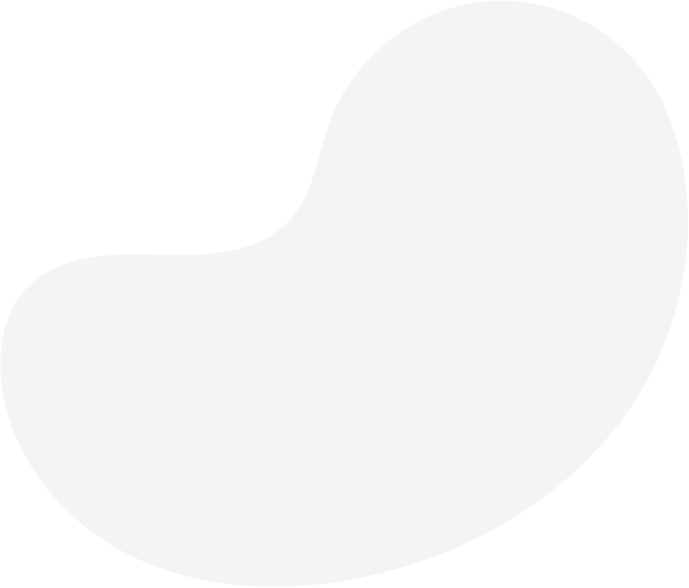

Key Modules for Manufacturing in ERPNext

Everything you need to manage a modern manufacturing business – in one integrated platform.

BOM & Product Engineering

- Multi-level Bill of Materials (BOM)

- Alternate and variant BOMs

- Version control for BOM & routing

- Standard vs actual consumption analysis

Production & Capacity Planning

- MRP & material requirement planning

- Work Order creation from Sales Orders

- Capacity planning by workstations

- Automatic scheduling & load balancing

Shop Floor & Execution

- Job Cards, operations, and routing

- Work in Progress (WIP) tracking

- Machine & labor time logging

- Production status boards & kiosks

Inventory & Warehouse Management

- Batch, lot, and serial number tracking

- Multi-warehouse, bin & location control

- Reorder levels & safety stock

- Stock ledger & valuation reports

Quality Control & Traceability

- Incoming, in-process & final QC inspections

- Inspection templates & sampling plans

- Non-conformance and corrective actions

- Traceability from raw material to shipment

Purchase & Subcontracting

- Supplier quotation & comparison

- Subcontracting with material supply

- GRN, purchase invoice & landed cost

- Supplier performance tracking

Sales, CRM & Dispatch

- Lead, opportunity & quotation management

- Sales orders linked to production

- Packing slips, delivery notes & invoices

- Customer-specific pricing & contracts

Integrated Accounts & Costing

- Auto posting from all manufacturing transactions

- Standard & actual cost comparison

- Cost center / project-wise profitability

- Complete financial statements in real time

HR, Maintenance & Compliance

- Shift scheduling & attendance tracking

- Preventive maintenance & asset management

- Document management & approvals

- Role-based access & audit trail

Built for Discrete & Process Manufacturers

ERPNext adapts to different manufacturing models – whether you produce standardized products, engineer-to-order, or run high-mix, low-volume operations.

Casting, machining, fabrication, assemblies

OEM suppliers, job work, tier vendors

Yarn, weaving, processing, stitching

Batch production, process & packaging

Our ERPNext Implementation Approach for Manufacturing

A structured, proven methodology to go live with minimal risk and maximum adoption.

Phase 1

Discovery & Process Study

Understand your business, map existing processes, identify gaps, and finalize the manufacturing scope, BOM structures, and key KPIs.

Phase 2

Solution Design & Configuration

Configure ERPNext modules, define masters, workflows, roles, and reports tailored to your manufacturing setup.

Phase 3

Data Migration & User Training

Migrate key masters and opening balances, conduct user training, and run pilot cycles for production, inventory, and finance.

Phase 4

Go-Live & Continuous Improvement

Stabilize post go-live, tune reports and dashboards, and continuously improve processes based on real-time data.

Tangible Results for Manufacturing Teams

Move away from manual follow-ups, spreadsheet chaos, and multiple disconnected tools. ERPNext brings your production, inventory, sales, and finance into one integrated system, giving leadership and shop floor teams a single version of the truth.

- Better on-time delivery performance with accurate production schedules

- Reduced inventory holding cost through smarter planning and MRP

- Improved quality with standardized inspections and traceability

- Real-time profitability view by item, customer, or order

- Faster decision-making with dashboards for management and operations

Sample Dashboards & Reports

- Production vs Plan Dashboard

- Machine Utilization & Downtime Report

- WIP Ageing & Bottleneck Analysis

- Material Consumption vs BOM Report

- Order-wise Contribution & Profitability

ERPNext for Manufacturing – FAQ

Get quick answers to commonly asked questions from manufacturing businesses.

Can ERPNext handle multi-level BOM and complex assemblies?

Yes. ERPNext supports multi-level BOMs, sub-assemblies, alternate BOMs, and version control so you can manage complex product structures with ease.

Does ERPNext support subcontracting and job work?

Absolutely. You can manage subcontracting by supplying raw materials to vendors, tracking their consumption, and valuing finished items correctly.

How does ERPNext help with quality control?

ERPNext provides inspection templates, QC checkpoints, sample-based testing, and non-conformance tracking to ensure consistent product quality.

Is ERPNext suitable for both make-to-order and make-to-stock?

Yes. You can run mixed manufacturing models (MTO, MTS, ETO) and link sales orders directly to work orders, MRP, and production plans.

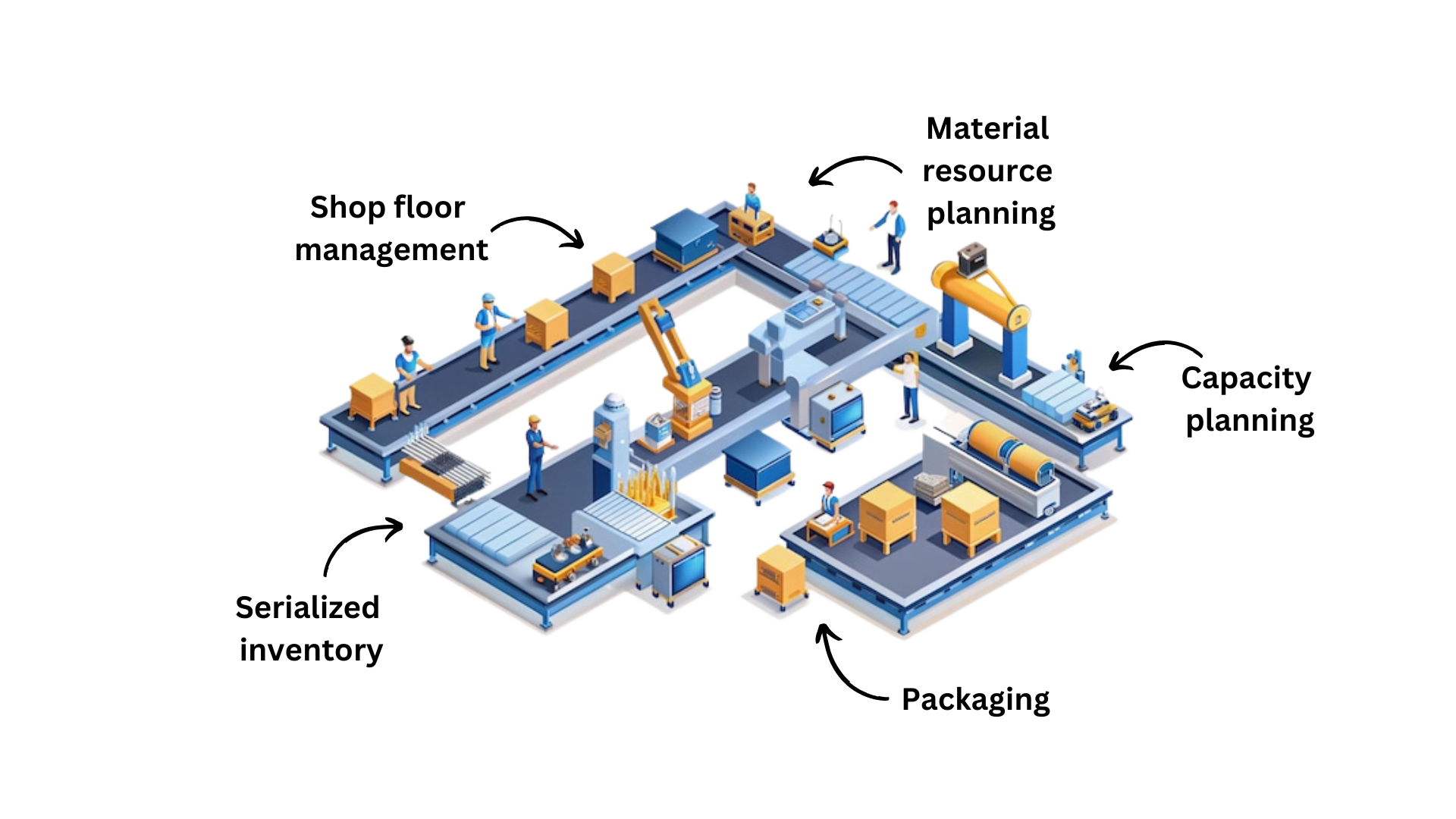

Hack, Make Production Entry in 3 Tap! ERP for Brass Industry

I've been using the BrassERP mobile application developed by MidoceanTech for a few months now, and it's made a significant difference in our manufacturing processes. The application is intuitive and user-friendly, and it's helped us streamline our operations and improve our efficiency. The real-time data and analytics have been especially helpful in making informed decisions. I highly recommend this mobile application to brass & metal manufacturing business looking to optimize their processes. best ERP for Brass Industries

Key Benefits of ERPNext for Manufacturing

Here are some key statistics that highlight the benefits of implementing ERP systems for manufacturing

0%

Reduction in operational costs

0%

Increase in productivity

0%

Reduction in manufacturing cycle times

0%

Reduction in errors

Production Planning

Inventory & Materials Management

Work Order Management

Bill of Materials (BOM)

Integrated Accounting & Reporting

Quality Management

Midocean Technologies specializes in ERPNext implementation for manufacturing industries. We understand the complex challenges manufacturers face and tailor ERPNext to meet your unique needs.

Whether integrating with third-party systems or transitioning from outdated software, Midocean ensures a smooth, disruption-free implementation process.

Our commitment doesn’t end after implementation. We offer continuous support, updates, and maintenance to keep your ERPNext system running at peak performance.

ERPNext is designed to scale with your business. Midocean Technologies ensures that your ERPNext solution is both cost-effective and adaptable as your business grows.

Our Impact in Numbers

Proven Success Through Key Metrics, Discover How We Achieve Results. Empowering Businesses with Data-Driven Insights

0+

Successful Implementation Delivered

0+

Years of Experience

0+

Countries Reached

0%

Client Retention Rate

Trusted by

60+ Companies

Frequently Asked Questions

Your Questions Answered: ERPNext Implementation and Customization

The timeline for ERPNext implementation varies based on the project’s scope and complexity but typically ranges from 4 to 12 weeks. We customize the process to ensure a smooth transition with minimal disruption.

We conduct a thorough analysis of your business requirements and workflows, then customize ERPNext modules and features to align with your unique processes, ensuring optimal performance and user adoption.

Midocean Technologies offers comprehensive post-implementation support, including troubleshooting, updates, and training, to ensure your ERPNext system continues to run smoothly and effectively.

Yes, ERPNext can be integrated with various third-party applications and software. We provide customized integration solutions to ensure seamless data flow across your existing systems.